W.G. Tomko, Inc. Service Division recognizes that a well maintained mechanical system ensures continuous system operations, maximizes operational efficiency, and helps to reduce costs associated with equipment repair or replacement. Our highly skilled technicians specialize in working on a variety of different mechanical systems. Whether it’s boilers, rooftop units, compressors, or chillers, our technicians have the expertise to keep your system operating efficiently.

W.G. Tomko, Inc. Maintenance Service Expertise:

Emergency Service / Repair

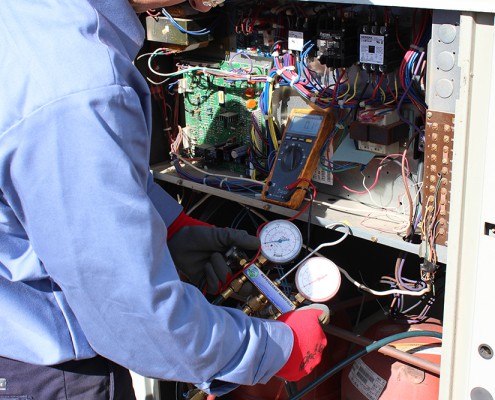

When your mechanical system needs servicing, our service technicians are there for you. Our technicians can service all brands of HVAC equipment. They have years of experience working with complex systems and bring their training and experience to any project. Our team has existing relationships with multiple manufactures and work in conjunction to find the best solution for at a client’s unique needs.

Start-Up / Commissioning

As your new building nears completion, our service technicians will perform the necessary start-up and commissioning of all your equipment to ensure that your equipment is functioning reliably before it goes into regular operation.

Equipment Replacement

W.G. Tomko, Inc. can replace critical pieces of your equipment or even replace entire systems depending on your need. When equipment failures do occur, W.G. Tomko, Inc. will work to minimize downtime and ensure the comfort of your tenant/patrons while our work is performed.

Redesign

When an existing system no longer accommodates the needs of a changing tenet requirements, W.G. Tomko, Inc. in house engineering capabilities can provide Redesign services to meet today’s modern energy efficiency goals, standards and codes.

Preventative Maintenance

Preventative maintenance is the most intelligent way to protect your investment in your mechanical system. Utilizing regular preventative maintenance can extend the useful life of your equipment and reduce the possibility of expensive repair or replacement. Our preventative maintenance agreements are tailored to meet the budget and operational needs of your facility.

All mechanical equipment is designed to operate within certain limits. Air conditioning and heating equipment are no exception, and if not properly maintained, the equipment will exceed its design limitations and fail. The best insurance against failure & cost containment is PM.

W.G. Tomko, Inc. understands the value of an effective preventative maintenance program that our client’s mechanical systems require. Our customized maintenance programs will keep your air conditioning and heating components operating properly.

Key Considerations when evaluating preventative maintenance:

- HVAC system maintenance isn’t expensive compared to what you might pay if your system degrades (and ultimately fails).

- By tracking and routine maintenance, you can detect emerging problems before they reach the crisis stage.

- It’s important to complete a life-cycle cost analysis when assessing whether you should repair or replace an aging HVAC system component.

Our Service and Maintenance Division is available 24/7 and our capabilities are as follows

Plumbing

- Booster Pumps

- Hot Water Heater

- Domestic Hot Water Boiler

- Storage Tanks

- Video Camera Testing

- Sewer and drain cleaning

- Certified Backflow testing

- Leak Repair

- Dye Testing

HVAC

- Combustion Analysis

- Computer room units

- Air handling units

- Make up air units

- Chillers

- Boilers

- Mini split System

- Pumps

- Variable refrigerant flow system

Air Handler Unit

Back Flow Preventer

Chiller

Control Panel

Cooling Tower

Heat Recovery

Variable Refrigerant Flow System

Domestic Hot Water Boiler

Mini Cassette

Preventative Maintenance

Roof Top Unit PM Testing

Snaking the Drain- Service

Camera – Service