CAPABILITIES

• GMAW Gas Metal Arc Welding

• FCAW Flux Core Arc Welding

• GTAW Gas Tungsten Arc Welding

• SAW Submerged Arc Welding

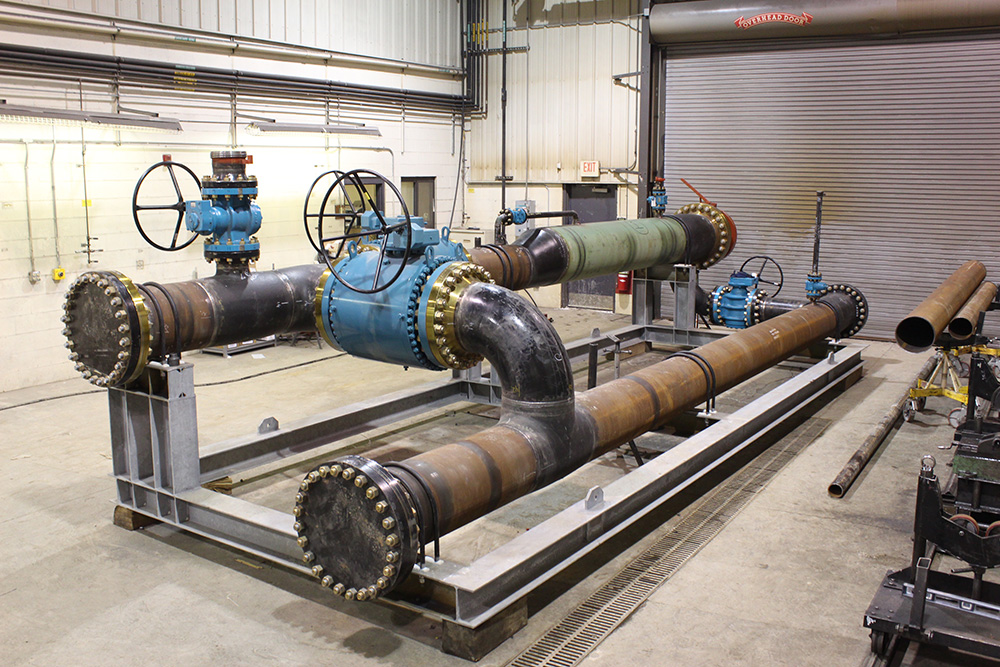

• API1104, ASME, and AWS Standards

• In-house Quality Control Department

• Custom Job Book furnished at Completion

• Covered outdoor material storage for staging

• 90, 000 Sqft. Fabrication facility with controlled conditions

• Hydrostatic Testing

CERTIFIED THIRD PARTY TESTING

• Radiography (RT)

• Ultrasonic (UT)

• Liquid Penetrant (PT)

• Magnetic Particle (MT)

• Visual (VT)

• Positive Material Identification (PMI)

EQUIPMENT

• Automated Pipe Cutting System – capabilities

support up to 60” pipe 1-1/4 wall thickness

• 12 welding stations with pipe positioners to

accommodate any size

• 2 Fifteen Ton Cranes

• Submerged Arc Welding Stations

PAINT AND BLAST BOOTH

• 50’X 25’X20’ Environment and Heat Controlled Blasting

• 20’X54’180’ Controlled Environment Paint Booth

• Baked/Heated Paint allows us to expedite our performance time

in project completion

• NASE Certified and In- House Coating Inspector

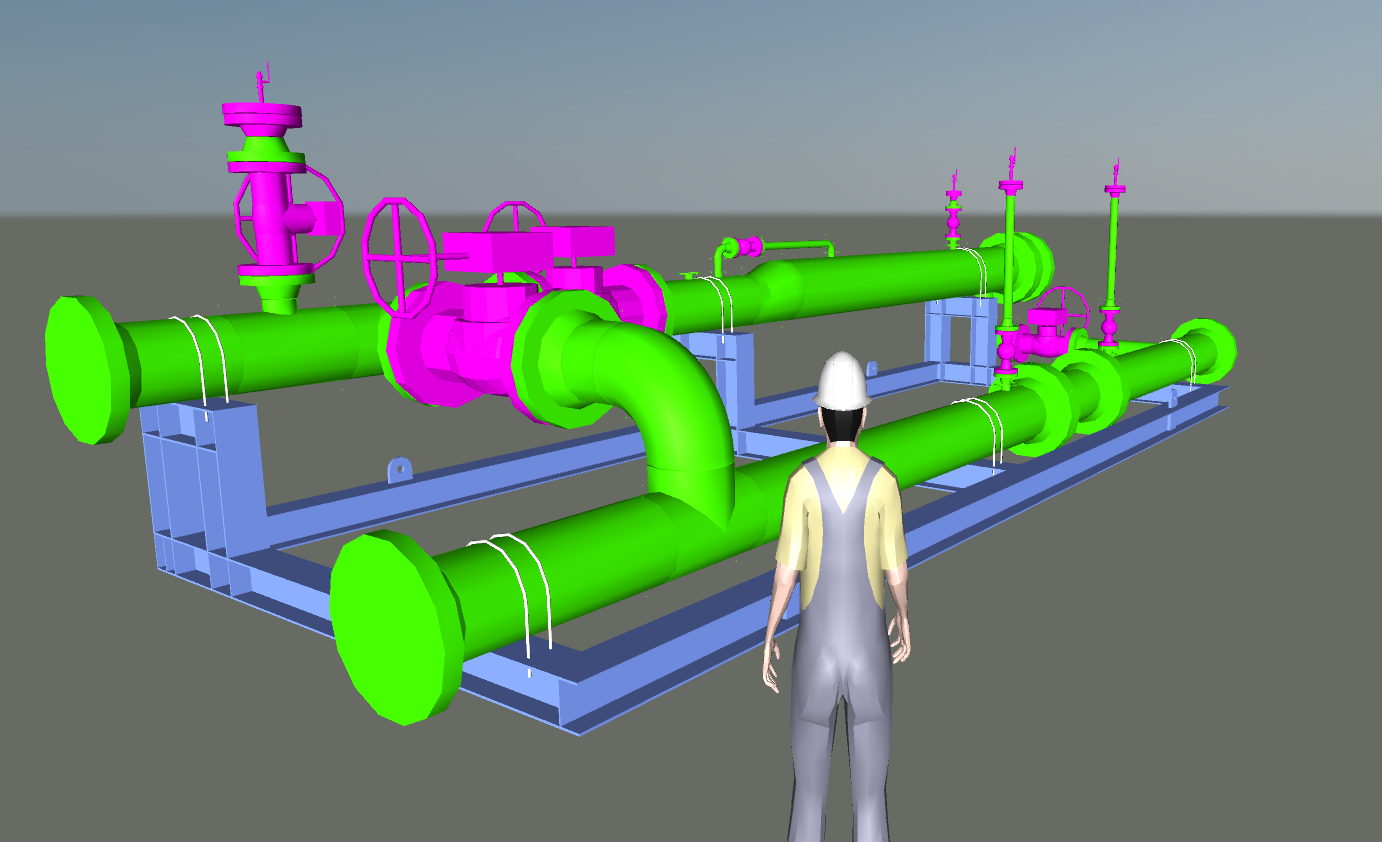

CAD CAPABILITIES

• Complete customized CAD designs or drawings for any type of

Launcher/Receiver, Metering, Fuel Gas Skid, Plant or Compressor

Fabrication