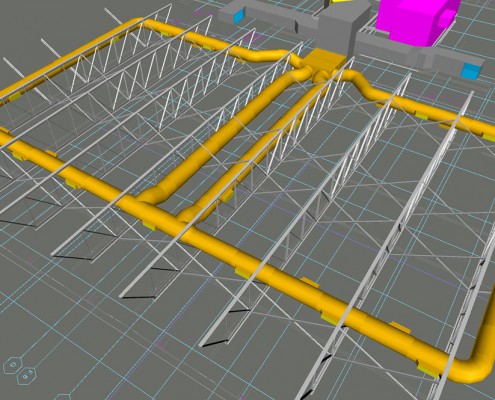

W.G. Tomko, Inc. In-house fabrication utilizing Lean Construction processes during project pre-planning, we identify areas of piping, plumbing, duct work, and equipment skids that can be pre-fabricated while the design is finalized and other construction takes place. Our fab shop have space for plumbers, pipe fitters, and sheet metal workers to pre-fabricate or construct modular components for all phases of work on our projects.

We are able to produce quality segments of work that are Bagged & Tagged and delivered to the construction site in time for installation. Through this process, we’re able to control the environment (potentially contributing to LEED credits), the quality, and the production levels in our fab shop, increasing productivity by lowering the crew sizes on the job sites.

From the time we begin estimate take-off, we approach every project with the attitude of “What can”t we prefabricate?” Utilizing Lean Construction thinking, we identify areas or entire systems of piping, plumbing, duct work and equipment skids that can be pre-fabricated while the design is finalized and other early construction takes place. Using our knowledge of green construction products and techniques, we help our clients evaluate the best and most practical solutions when seeking LEED certification for their projects.

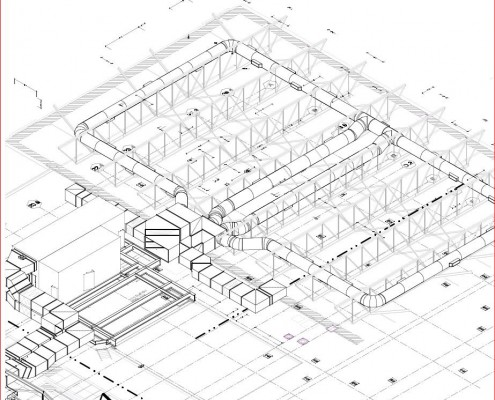

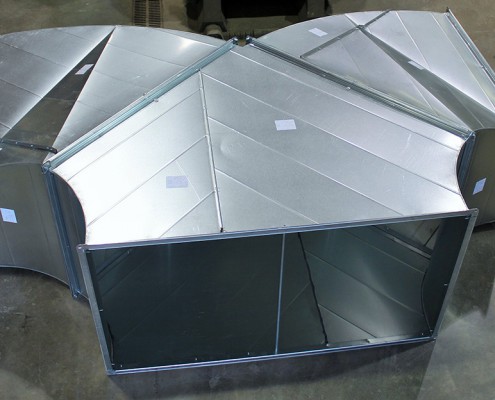

Sheet Metal Fabrication Capabilities

We fabricate and install all of the sheet metal duct work for our projects in-house from our automated workshop. Performing this work on-site gives us full control over fit, quality, and craftsmanship. It also allows us to better coordinate our projects’ timelines to ensure they are completed on time.

All materials are proudly manufactured and carries the “Yellow Label” Union Label.

- Round Ductwork

- Spiral Ductwork from 4 ” thru 50 “.

- Galvanized gauges from 26 thru 18 gauge.

- Galvaneel gauges from 26 thru 18 gauge.

- Stainless gauges 24 thru 20 gauge.

- Aluminum gauges 24 thru 16 gauge.

- Gasket and non-gasket fitting

- Flanged connection available.

- Square Ductwork

- Any Material any gauge any SMACNA pressure class

- Coil Line rectangular ductwork lined or unlined

- Any fittings can be made with our state of the art CNC Plasma Table.

- Fully welded ductwork is available.

- Shop drawings or coordination can be produced.

Pre-Fab Piping Capabilities

Prefabrication maximizes the strategy of removing labor from the field and implementing as much labor as possible in a controlled environment. The benefits include increased productivity, greater quality control, shorter on site durations saving time on the project schedule, and improved overall project safety. The bottom line means lower costs for the client.

- Coil connections and assemblies

- Pump assemblies

- Weld spool for gas and comfort heat piping

- Plumbing assemblies

- Hangers of any type

- Structural Steel

- Control valves

- In-wall fabrication

- Medical gas assemblies

- Plumbing fixture batteries

- PVC

- Copper fabrication of all types

- Trim fixtures

- VAV boxes